The use of traditional disposable face masks has seen huge increase under the pandemic. Such mass consumption inevitably leads to environmental and ecological scourge. A local start-up, ÖKOSIX, has invented the world’s first biodegradable and compostable surgical mask that decomposes into carbon dioxide, water and organic matter in six months. Development potential is very promising.

According to estimation of the World Health Organization (WHO), the number of face masks disposed went up to 4.5 trillion in 2020. Based on Hong Kong’s 7.5 million population that includes approximately 4 million working people, millions of disposable face masks are consumed daily during the COVID pandemic. The environmental and ecological price tag is high.

A child’s innocent comment motivated the development of green masks

ÖKOSIX Founder Eddie Yu was running a face mask brand with a multi-million dollar turnover in 2020. One day his young niece said to him, “Your masks are environmentally irresponsible”. That casual yet thought-provoking comment made him reimagine his business.

ÖKOSIX Founder Eddie Yu was running a face mask brand with a multi-million dollar turnover in 2020. One day his young niece said to him, “Your masks are environmentally irresponsible”. That casual yet thought-provoking comment made him reimagine his business.

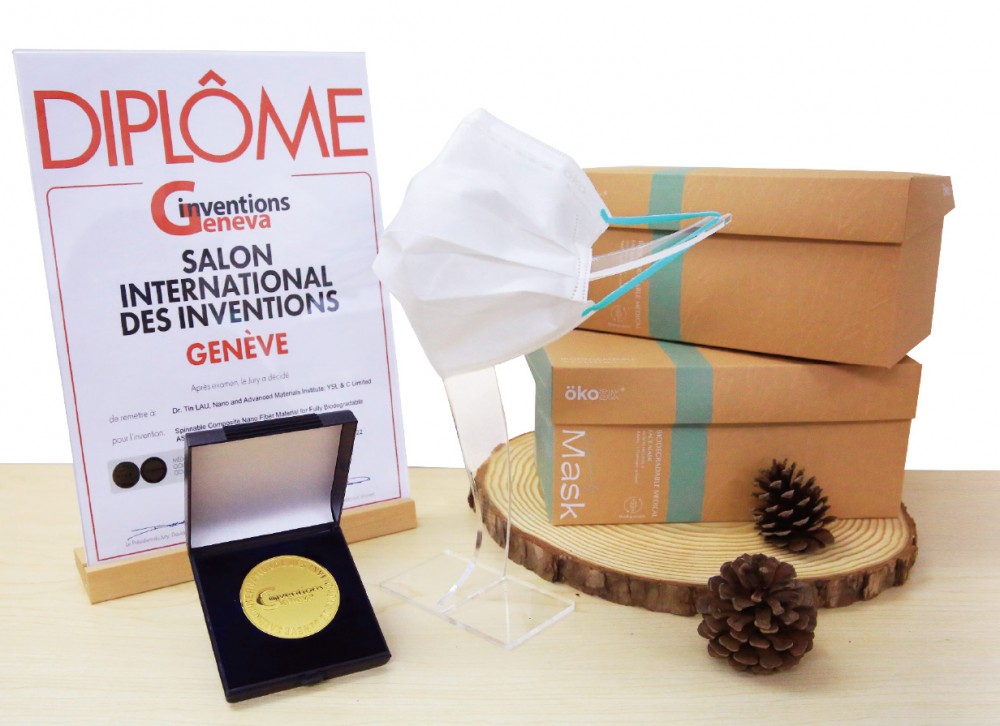

He quickly remembered Nano and Advanced Materials Institute (NAMI), an organization he encountered at a forum some years ago. Knowing that NAMI has a long history in research on biodegradable materials, he contacted them to discuss collaboration right away. The deliverable of this joint effort is the world’s first zero-plastic medical-grade face mask. The technology has now obtained several certifications and ÖKOSIX gained admission to Hong Kong Science Park and received grants from the Innovation and Technology Commission. More encouragingly, the company clinched a gold medal at the Geneva International Exhibition of Inventions 2022.

A vision of zero-plastic lifestyle and positive social atmosphere

“We use plant fibers and natural substances to produce nano filters and materials which offer higher filtering capacity and permeability. As well as being plastic free, these materials are made with a process more energy efficient than the traditional method.” Yu also pointed out that the unit price of his masks is HKD4 to HKD5, which is comparable to other good-quality masks on the market. He hopes to do his bid to mitigate the global plastic pollution issue.

“We use plant fibers and natural substances to produce nano filters and materials which offer higher filtering capacity and permeability. As well as being plastic free, these materials are made with a process more energy efficient than the traditional method.” Yu also pointed out that the unit price of his masks is HKD4 to HKD5, which is comparable to other good-quality masks on the market. He hopes to do his bid to mitigate the global plastic pollution issue.

The masks are now in trial production and each machine is estimated to produce tens of thousands of masks daily. These in-house made ÖKOSIX masks will be available in major retail outlets. Yu also revealed a plan to develop and manufacture biodegradable air filters in the coming year, and to expand the product portfolio to include biodegradable paper diapers, sanitary napkins and other consumables in 2025.

Yu sees a shift of thinking that places emphasis on ESG and sustainability. ÖKOSIX is receiving enquiries from many businesses, indicating interest in ordering biodegradable masks. He believes there is great market potential for this kind of material.

Fostering green consumption habits in the community

Some masks on the market claim to be degradable. However, Yu is skeptical about the time required for decomposition and the contents of degradable materials. Studies have also found that common surgical masks will release micro-plastic over time, so long-term use might pose health hazards. Yu believes his products are highly competitive, and he welcomes competition from similar products. “Let’s offer more health products together and make contributions to environmental protection.”

Some masks on the market claim to be degradable. However, Yu is skeptical about the time required for decomposition and the contents of degradable materials. Studies have also found that common surgical masks will release micro-plastic over time, so long-term use might pose health hazards. Yu believes his products are highly competitive, and he welcomes competition from similar products. “Let’s offer more health products together and make contributions to environmental protection.”

Looking back on his start-up journey, Yu is so happy that in the eyes of his young niece he has transformed from “a bad uncle who makes environmentally irresponsible products” to “a good uncle who drives environmental protection”. He indicated he will strengthen marketing efforts in the future to raise awareness and exposure for his products so they can substitute traditional surgical masks in the long run.